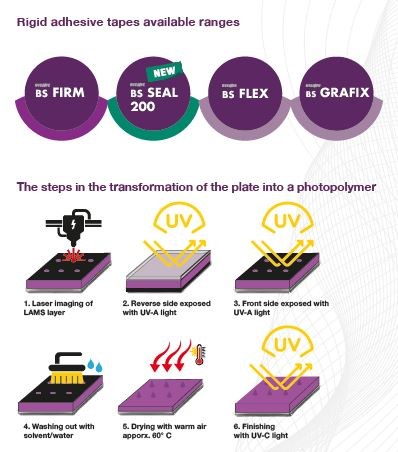

BS SEAL 200

It is the most advanced solution in the process of laminating the plate to thepolyester support for printing in the corrugated cardboard sector.

It is the most advanced solution in the process of laminating the plate to thepolyester support for printing in the corrugated cardboard sector.

Designed to satisfy reprohouses that adopt the highest standards.

Distinctive features

Innovative surface structure: The liner has been specially designed to imprint an irregular pattern on the adhesive, optimising air distribution, reducing the risk of air bubbles and ensuring uniform adhesion over a large contact area.

Solvent Resistant: a specially formulated adhesive that combines maximum

adhesion and resistance to solvents used in washing the plates, ensuring maximum

versatility.

Advanced Protection: The name “SEAL” reflects the product’s ability to seal,

creating an effective barrier against external agents, preventing infiltration of inks

and solvents, improving the final yield and optimising the workflow.

Use and Benefits

Perfect for repro houses: Simplifies plate mounting, improving precision and

productivity.

Versatile: It easily adapts to the process chosen by the customer. It can also be used for application before the solvent washing cycle and drying of the plate, thanks to its composition of adhesive and PET support.

Product resistance

Technical data sheet

The Research and Development department of BiesSse has developed a product characterized by:

a PET support

a polypropylene (PP) liner

a unique adhesive resistant to solvents, UV rays and high temperatures

Below are the characteristics of two solvents often used in the washing phases with which the photopolymers remain in contact for about 20 minutes.